Introduction

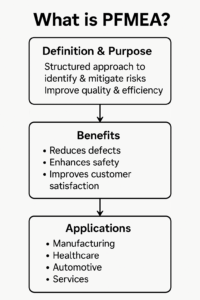

Process Failure Mode and Effects Analysis (PFMEA) is a structured method used to identify, evaluate, and mitigate risks in a process. It ensures process stability, enhances product quality, and improves operational efficiency. This comprehensive guide will take you through a detailed 6-hour course format, covering both foundational and advanced aspects of PFMEA.

Chapter 1: Understanding PFMEA

Lesson 1: What is PFMEA?

- Definition and purpose

- History and evolution of PFMEA

- How PFMEA compares to other risk management tools

Lesson 2: Benefits of PFMEA

- Enhancing quality and reducing defects

- Cost reduction and financial benefits

- Terminologies

- Failure Mode and its impact on business operations

- Effects of Failure: Safety hazards, f

- Compliance with industry standards (ISO 9001, IATF 16949, etc.)

- Case studies on successful PFMEA implementation

Lesson 3: Key

- inancial implications, delays

- Severity (S), Occurrence (O), Detection (D) – Detailed explanation and examples

- Risk Priority Number (RPN) – Calculation and practical application

Leave a Reply