In today’s rapidly evolving manufacturing landscape, Process Failure Mode and Effect Analysis (PFMEA) plays a crucial role in identifying and mitigating risks before they escalate. As industries continue to embrace innovation, advanced PFMEA strategies that integrate Artificial Intelligence (AI), machine learning, automation, and methodologies like Lean Manufacturing and Six Sigma are transforming how businesses manage quality control, waste reduction, and defect prevention.

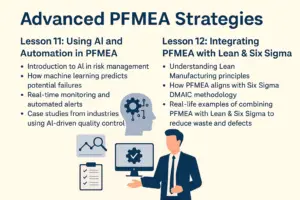

Using AI and Automation in PFMEA

Introduction to AI in Risk Management

Artificial Intelligence (AI) has revolutionized the way risk management is approached in industries. Traditionally, PFMEA involved manual assessments to identify potential failures, but AI and automation have significantly increased efficiency by offering real-time data processing and predictive insights.

AI algorithms analyze vast amounts of data and detect patterns that would be difficult for humans to identify. These predictive models can foresee potential risks and failures based on historical data, providing manufacturers with the foresight to prevent issues before they occur. With AI, risk management becomes a proactive and dynamic process.

How Machine Learning Predicts Potential Failures

Machine learning (ML), a subset of AI, plays a critical role in predicting potential failures in PFMEA. By training algorithms on historical failure data, machine learning models can recognize trends and anomalies that may indicate future failures. This predictive ability allows organizations to take preventive action ahead of time, improving the quality of products and processes.

For example, an automotive manufacturer might use machine learning to analyze past defects in the assembly line. The algorithm will learn to predict when and where similar defects are likely to occur, helping engineers to focus on preventative measures before the issue arises.

Real-Time Monitoring and Automated Alerts

One of the most powerful benefits of incorporating AI and automation into PFMEA is the ability to monitor processes in real-time. AI-powered systems can track equipment performance, environmental conditions, and process variables, sending instant alerts if something is going wrong.

For example, if a piece of machinery begins to show signs of wear that could lead to a failure, the AI system can automatically notify the team, enabling them to address the issue promptly. This real-time intervention ensures that problems are addressed before they escalate into bigger issues, thereby reducing downtime and minimizing production delays.

Case Studies from Industries Using AI-Driven Quality Control

Many industries have successfully implemented AI-driven quality control systems to enhance their PFMEA processes. A notable example is the use of AI in the semiconductor industry, where machine learning models are used to predict and detect defects in microchips before they leave the production line. In the automotive sector, AI-powered systems are deployed to monitor production quality and predict the lifespan of critical parts like engines and transmissions.

These case studies highlight how AI can be leveraged to create smarter, more efficient quality control processes, leading to higher productivity and cost savings.

Integrating PFMEA with Lean & Six Sigma

Understanding Lean Manufacturing Principles

Lean Manufacturing is a methodology that focuses on reducing waste while improving quality and efficiency. The primary objective is to eliminate anything that does not add value to the end product. By streamlining processes and optimizing resource utilization, companies can deliver higher-quality products at a lower cost.

When PFMEA is combined with Lean principles, the focus shifts towards identifying and eliminating risks associated with waste and inefficiency. This results in more streamlined operations and a reduced likelihood of failures due to suboptimal processes.

How PFMEA Aligns with Six Sigma DMAIC Methodology

Six Sigma is a data-driven methodology that focuses on improving quality by eliminating defects and reducing variability in processes. The DMAIC (Define, Measure, Analyze, Improve, Control) framework is at the core of Six Sigma’s approach.

When PFMEA is integrated with Six Sigma, it complements the DMAIC methodology by identifying potential failure modes at each stage of the process. For example:

Define: Identify the process steps and the potential failure modes using PFMEA.

Measure: Collect data on the process’s current performance and failure frequencies.

Analyze: Use the data to identify root causes of defects and failure modes.

Improve: Implement changes to reduce failure modes and enhance process performance.

Control: Use PFMEA to ensure that improvements are sustained and that new potential risks are continually monitored.

Real-Life Examples of Combining PFMEA with Lean & Six Sigma to Reduce Waste and Defects

In many industries, the combination of PFMEA with Lean and Six Sigma methodologies has led to significant improvements in efficiency and defect reduction. For example, in the healthcare industry, PFMEA is used alongside Lean practices to improve patient care while reducing waste in administrative and operational processes.

In the manufacturing sector, companies have successfully combined PFMEA with Six Sigma to reduce defects in production lines. By applying PFMEA to identify potential failure modes and then using Six Sigma’s DMAIC approach to address the root causes, organizations have seen improvements in product quality, lower defect rates, and reduced operational costs.

Leave a Reply